|

Dear Sir or Madam,

Today we would like to inform you about newly published FOSTA final reports from the fields of mobility, construction and mechanical engineering.

These and all other FOSTA reports can be found at shop.stahldaten.de

We would like to wish you now an interesting reading.

Your FOSTA team

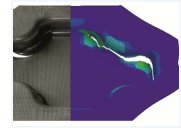

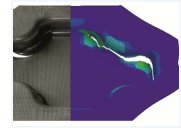

| P 1039 - Enhanced Continuum Damage Mechanics Model for Low Triaxialities for the Deep Drawing Simulation of Advanced High Strength Steels

Advanced high strength steels are still a common choice for lightweight design in the automotive industry. Due to their good performances such as high strength and high energy absorption, these steel grades are excellent for body in white components. Because of their restricted ductility, which sometimes leads to the formation of cracks without or with low necking during forming operations, the conventional forming limit diagrams may fall short. As a remedy, continuum damage models are commonly applied in the literature to predict failure due to fracture. read more

|

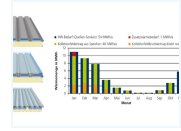

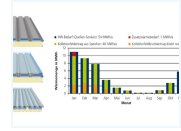

| P 1041 - Optimisation of the operating principle and the use of energy in sandwich construction with energy accumulation, energy distribution and insulation

Industrially manufactured sandwich elements with additional trapezoidal steel sheets on the outside were connected together in the FOSTA project P 779 to form the so-called SEA air collector (SEA = Sandwich Energy Accumulation). Due to the cross-section of the trapezoidal steel sheets, channels are created on the outside when the individual components are joined together, through which air can flow. When the sun shines on the south facade and the roof surface, the SEA air collector can produce an annual energy yield of approx. 160 kWh/m² in the form of heated air. Within the scope of the present project, it was investigated how a further improvement of the energy yield of this collector can be achieved by optimizing physical and design parameters. read more

|

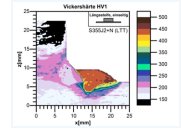

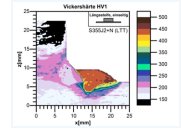

| P 1060 - Fatigue strength improvement of high strength steel welds by new LTT-filler materials

The use of LTT filler materials represents an alternative approach to the usual methods of weld post-treatments for increasing the fatigue resistance of welded steel structures. The essential mechanism is based on the influence of the low martensite start temperature on the residual stress state already during welding. As a result, the compressive residual stresses from the hindered volume expansion due to phase transformation become fully effective. Furthermore, the weld has a high hardness, which can delay the formation of cracks, but also leads to a low notched bar impact energy. In the present research project, fundamental investigations were carried out into the welding processing of an LTT filler material. This includes ensuring weldability and characterizing the joint properties. Investigations into weldability made it clear that safe use is possible in the working range available for high-strength steels. The Cr-Ni-based LTT filler can be joined with high weld seam quality. The mechanical properties also allow the use in the field of high-strength steels with a yield strength of 960 MPa. There is potential for development in terms of toughness. The notch impact values achieved in this work are significantly lower than commercially available conventional weld met- als. The investigations prove that the impact of the martensitic phase transformation has an effect on the entire weld metal. The intended high compressive residual stresses are mainly found in bulk of the weld metal. read more

|

| P 1101 - Overhead line tower for the energy turnaround in consideration of architectural, technical and economic aspects

The politically driven energy turnaround requires numerous expansion and grid strengthening measures. Steel overhead line masts are still almost exclusively lattice masts, which were already controllable 100 years ago in terms of planning, production technology and calculation. Today, however, these are often considered a visual disturbance or an impairment of the aesthetics of the landscape and the townscape. This research project aims to improve the image of overhead lines and make them a necessary and accepted part of our industrial society. The aim is to develop a new type of overhead line mast made of steel which, in addition to meeting the highest technical and economic requirements, also meets the requirements of the energy turnaround in its design. Therefore, the work has been carried out by engineers and architects in an interdisciplinary way. read more

|

| P 1118 - Influences of steel and composite construction on life cycle costs and marketability of multifunctional office and commercial buildings

The demographic change and the increasing awareness of sustainability are examples of changing social conditions, which affect the user requirements of multi-storey buildings. Resource conservation, recyclability, lifecycle costs and conservation of value, even under changing property conditions, are increasingly in the focus of planning. Among other things, the competitiveness of rented and usable space depends on whether the spaceforming structures offer the necessary flexibility to adapt to these dynamic processes. Experiences of the past decades show that the establishment of cost-effective monofunctional building structures and neighbourhoods, as they have been built in many cities since the 1970s, often result in an early vacancy up to a demolition, as a consequence of an insufficient adaptability of the primary structure. read more

|

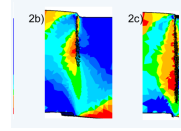

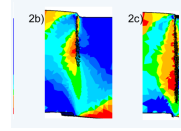

| P 1127 - Material sience-based development of simulation strategies for the application of adiabatic cutting in sheet metal part manufacturing

Steels with tensile strengths larger than 1000 MPa are widely used in the automobile industry to reduce the amount of used material and pursue lightweighting. Virtually every sheet metal component undergoes a material separation process during its manufacturing. Conventional blanking or fineblanking cannot be used for high strength steels without extensive pre- or post-operations. Adiabatic blanking offers an alternative to conventional blanking or to cost-intensive laser trimming. It has been shown already that this process produces cut edges with a high quality concerning straightness, roundness and surface finish. read more

|

| On our own behalf

Dear Sir or Madam,

in spite of the current restrictions, we try to maintain the usual project operation in the FOSTA research projects as far as possible. Since the beginning of March 2020, we have been consistently managing all project meetings via web conference. Thus we can already look back on many positive experiences for the participants and for the progress of the project.

In the current 119 ongoing FOSTA research projects, we continue to give around 3,500 participants from science, industry and public authorities the opportunity to become professionally involved in the projects. This offer has been very well accepted and confirms our current approach in project management. We will maintain this arrangement until normal operation without any health risk for all participants are possible again.

For current and newly approved FOSTA research projects, you will receive the corresponding project invitations from us as usual. We will provide you with the necessary access data for a web conference.

You can still reach us under our regular contact details. If possible, please use the digital way to transmit information. We look forward to your professional support in the future as well in the context of digital participation in our research projects.

Stay healthy!

Your

FOSTA Team

|

|

|

|