|

Dear Sir or Madam,

Today we would like to inform you about newly published FOSTA final reports from the fields of mobility, construction as well as plant and mechanical engineering.

These and all other FOSTA reports can be found at shop.stahldaten.de

We would like to wish you now an interesting reading.

Your FOSTA team

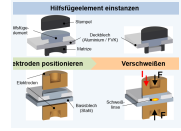

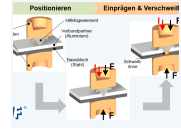

| P 1010 - Pre-hole-free joining of steel-intensive lightweight structures by means of resistance element welding with pre-assembled structures (IGF-No 18392 N)

In recent years, the automotive industry has, due to legal requirements, increasingly focused on lightweight construction measures, especially in the body structure using various lightweight materials in accordance with the load. For the realization of lightweight but nevertheless rigid and crash-resistant body structures in monocoque construction, a mixed construction method is particularly suitable for series production, in which high-strength and ultra-high-strength, press-hardened sheet steel parts are combined with aluminum materials. The thermal-mechanical joining processes developed in recent years to series maturity and not exclusively for this application offer a high application potential and the first series applications have already been made. Due to the novelty of resistance element welding, the process-related properties and characteristics have so far been insufficiently investigated, so that sufficient knowledge about the welding, strength and failure behavior of corresponding joints and material combinations is lacking. more information

|

| P 1030 - Repair concepts for lightweight structures in the body repair (S 024/10215/14)

Within the framework of the project, the state of the art in the field of "Joining and Repair" of automotive joining technologies was recorded and the main challenges derived from this. These are, on the one hand, the removal of bonded joints in general and in particular in combination with high-strength steels. Currently, if necessary, an adhesive connection is chiselled or peeled with great mechanical effort. This can be done with the aid of heating, but is often undefined. In newer designs, peeling is no longer possible due to the use of high-strength steels and the high rigidity of the components. This was the starting point for more in-depth investigations. more information

|

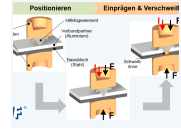

| P 1054 - Joining of high-strength steel grades in lightweight structures by means of self-piercing resistance element welding on conventional resistance spot welding machines IGF-No 19215 N)

The object of this research project is the development of a novel resistance element welding (REW) process for joining high-strength steels in combination with aluminum alloys. Compared to the current state of the art, a single-stage process and thus the use of conventional resistance welding technology are planned for both the insertion and the welding of the joining partners. The implementation of the results obtained will make an important contribution to the further development of resistance element welding and the economical manufacture of future steel-intensive lightweight structures in mixed construction. more information

|

| P 1139 - Rise of temperature in hollow spaces of suspended ceilings, in hollow space floors and access floors and its effect on the load-bearing capacity of inner steel elements (IGF-No 18894 N)

Modern buildings must fulfil functional, economic and ecological requirements in order to achieve climate protection goals. An integral part of these buildings is integrated and multifunctional slab systems, which includes the integrated and sustainable composite slab system InaDeck. Multifunctional slab systems must fulfil the performance criteria R (load-bearing capacity), E (fire integrity) and I (isolation) for a fire resistance time of up to 90 minutes according to the ISO standard fire curve applied below the slab system. In addition to the fire protection requirements for a fire scenario below the slab system, further fire protection requirements (R30) are demanded of the load-bearing structure of the slab system, which is located in suspended ceilings as well as in hollow and raised floors. Recent research results have shown that the fire protection requirements (R30) of the slab systems with the ISO standard fire curve is very conservative. The research project is dedicated to the question of the development of a natural fire scenario for the hollow space of the slab systems for a realistic assessment of the load-bearing behaviour of the slab system InaDeck in case of this developed natural fire scenario for the hollow space. more information

|

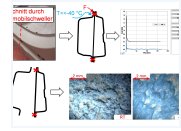

| P 1241 - Study of the influence of constructional siffness of thick laser and laser hybrid welding joints on the hot crack formation (IGF-No 19582 N)

In the framework of this research project to investigate the influence of the structural stiffness of thick-walled laser and laser hybrid welded joints on hot crack formation, the restraint intensities during welding were varied by means of hot crack tests in order to obtain a relationship between the restraint intensities and crack formation. After modifying a testing machine, it was possible to simulate different restraint intensities in the context of the reaction forces. Experiments were carried out for different materials and welding methods to determine the critical range of restraint intensity where solidification cracks occur. more information

|

| P 1200 - Innovations for the optimal use of weathering steel in steel and composite bridge construction (IGF-No 18655 BG)

Weathering steel is characterized by a much higher corrosion resistance compared to unalloyed structural steel. On the surface of the unprotected weathering steel, natural corrosion processes form a tightly adhering, compact layer that slows down further corrosion. Due to the slower corrosion reaction of the weathering steel, the use under natural corrosion conditions is possible and permissible even without an additional corrosion protection system. Since many steel and composite bridges in Germany show age and construction-related damage, there is a great demand for durable and low-maintenance replacement bridges. Due to its naturally occurring and maintenance- free corrosion protection, the corrosion-resistant weathering steel can provide this as a construction material in bridge building. more information

|

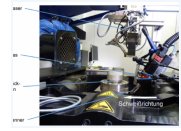

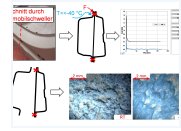

| P 885, P 965, P 1048 – DFG / AiF-Research Cluster Dry Shearing

Hybrid composite materials exhibit a broad range of functional properties which can be adapted to the high requirements of new products. They are therefore particularly suitable for the application in lightweight products and as well for many other application fields. However, the lack of serial processing methods prevents the use of such materials in industrial mass products. Therefore, the shearing process, which is very important for industrial production, has been scientifically investigated within the scope of this AiF/DFG collective research project. The process has been further developed for the cutting of multilayer and two-layered metals as well as polymer laminates. In order to avoid function impairment of the composite, special attention has been paid to the avoidance of delamination, indentation, or tearing of the outer layers during the cutting process. In addition, no additive process-improving lubricants were used to rule out undesired interactions between the polymer layers and the commonly used lubricants as well as their cleaning agents. The aim of the project was, thus, the development of approaches for designing the manufacturing process and the related tool, which will be the basis for the industrial application of dry cutting of different layer composite materials. more information

|

| P 642 – Improvement of the notched geometry to increase the fatigue strength of high strength and stainless steels by process control and innovative treatment for laser and arc welding and brazing (S 24/10086/04)

The aim of the project was to achieve higher fatigue strength (ideally up to that of the base material) by improving the seam geometry of fillet welds at lap joints (sheet thickness s = 2mm). For this purpose, the process control of already known and established joining methods (laser beam welding and soldering, MSG welding, MSG soldering, laser-MSG hybrid welding) was first optimised for two steels, a high-strength ferritic-martensitic dual-phase steel (DP-W600/1.0936) and a stainless austenitic steel (H400/1.4376). The influence of the energy intensity and its distribution during welding, the influence of the welding or brazing filler metals and the shielding gas on the weld transition radius and weld rise were investigated. Furthermore, in the MSG brazing processes, an attempt was made to reduce the influence of the seam geometry by thermal post-treatment using the combined MIG-WIG process. In order to ensure the implementation of the results in industrial production, the transferability of the processes to a demonstrator component was also be examined. more information

|

| P 1208 – Consistent design model for production-optimized composite dowels – Basis for DASt guideline and transfer to Eurocode 4 (IGF-No 19438 N)

This report summarises the investigations carried out on the load-bearing and deformation behaviour of composite dowels in the field of building construction. The competitiveness of these economically and technically useful shear connectors is limited in comparison to conventional head studs by the fact that only a national and time-limited approval is currently available. In order to contribute to the integration of the composite dowels into the European standards, the participating research institutions concentrated on the investigation of composite dowels in cracked and non-cracked concrete, under longitudinal shear, tensile and combined shear-tensile loads as well as in positions close to the surface. New failure mechanisms could be observed and described by design formulas. more information

|

|

|

|