|

Dear Sir or Madam,

Today we would like to inform you about newly published FOSTA final reports from the fields of mobility, construction as well as plant and mechanical engineering.

These and all other FOSTA reports can be found at shop.stahldaten.de

We would like to wish you now an interesting reading.

Your FOSTA team

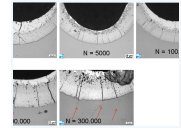

| P 925 -Experimental and theoretical assessment of the fatigue strength of large bolts under consideration of the thin surface layer influence (IGF-No 486 ZN)

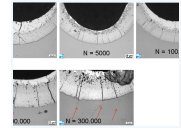

Large-size bolted connections under cyclic loading are applied in the wind energy sector but also in other applications of structural engineering in form of HV-bolt sets. An economic, reliable and durable corrosion protection is commonly achieved by hot-dip galvanizing. However, the influence of the zinc coating on the fatigue characteristics of bolts with large dimensions has currently not conclusively been analyzed. Moreover, characteristic values for fatigue design are thus far mostly validated on bolts with smaller diameters. Aim of this research project is the extension of existing design methods for bolts with large dimensions and the development of an analytical assessment method based on local stresses and strains. To this end, the effect of hot-dip galvanizing on the fatigue strength as well as the underlying damage mechanism are systematically analyzed. more information

|

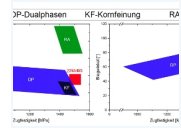

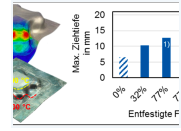

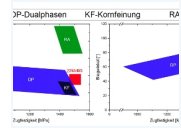

| P 1110 - Local laser heat treatment of strain hardened steels enhancing forming and functional capabilities for automotive light weight concepts (IGF-No 18845 N)

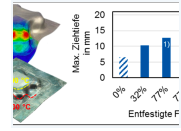

The overall research objective of the project was to combine cold rolling and local laser heat treatment in steel blanks to achieve tailored properties in terms of formability and crash behavior for the following forming process as well as subsequent use in the automobile. To investigate this approach, a cost-efficient ferritic steel, the micro-alloyed S550MC, and an established steel with high application relevance, the dual-phase steel HCT780X, were selected.

First, the temperature ranges in which relevant softening mechanisms occur depending on the degree of rolling were determined. For this purpose, short-term heat treatments based on the laser softening were carried out in a deformation dilatometer. The resulting mechanical properties were then tested at room temperature in a tensile test. The results serve on the one hand as a target value for the process development of the local laser heat treatment and on the other hand as a basis for the material data required in the simulation. more information

|

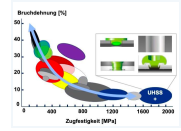

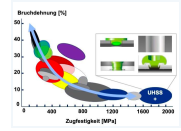

| P 1133 – Development of hybrid joining technologies without pre-hole for ultra-high strength steels with tensile strength above 1.800 MPa in multi-material structures (IGF-No 18866N)

The automobile industry focuses on light weight constructions because of the legal requirements to reduce the production of carbon dioxide. The decrease of carbon dioxide production to average 95g CO2/km in the passenger car market is determined until 2020.

Because of its 30% fraction of the gross vehicle weight the body in white has the biggest potential for light weight constructions using ultra high strength steel in thin sheet thicknesses and lightweight materials like aluminum. Especially the multi material construction of press hardened steel (22MnB5) and aluminum combined with the adhesive bonding leads to economical light-weight solutions. Even higher light weight grades can be achieved by using even stronger steels with strengths above 1800 MPa (in this report called as “UHSS+”). Thus, a further reduction of the material thickness can be achieved, wherein the component performance is substantially maintained. more information

|

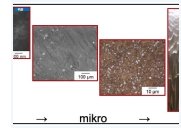

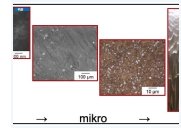

| P 1125 – Enhancing technological properties of tool steels by cryogenic treatment (IGF-No 19289 N)

The aim of the project was to investigate the effects of cryogenic treatment on the microstructure, mechanical properties and wear resistance of the high-alloyed tool steels X38CrMoV5-3 (electroslag remelting (ESR)), X153CrMoV12 (powder metallurgy (PM) and melting metallurgy (MM)) and ~X190CrVMo20-4 (PM). The tempering parameters for the mechanical specimens and for the wear samples were selected on the basis of the tempering curves in such a way that a similar hardness was achieved for both the conventionally heat-treated and the cryogenically treated samples. more information

|

| P 1290 – Determination of influencing factors and elaboration of effusion parameters for a safe use of high-strength steel components endangered by hydrogen induced damages (IGF-No 19798 N)

In the metal processing industry, especially in the automotive industry, the use of highstrength or ultra-high-strength steels has increased steadily in recent years. However, these steels exhibit a high risk of hydrogen embrittlement. During the production of high strength material components there are several procedures where hydrogen is brought in. Heat treatment steps which are used to reduce the hydrogen content are often performed for longer periods than necessary due to a lack of knowledge of the effusion mechanisms.

In this research project, the influence of materials and micro structures on hydrogen diffusion, absorption and effusion are examined. The aim is to calculate effusion times and temperatures that are sufficient to reduce the hydrogen content to an uncritical level. Effusion diagrams should be calculated as an assistance for the heat treatment in production facilities of SMEs. more information

|

| P 1248 – Qualification of the instrumented indentation technique for the parameter identification of advanced high strength steels (IGF-No 19550 N)

The determination of mechanical properties of welded steel structures such as strength or ductility is a subject of high interest for the majority of companies in the area of metal processing. The material parameters can be obtained by performing the tensile test on the samples made from a part of a component. In some cases, it is highly expensive to produce the tensile specimens especially from the weld metal, which contains different type of microstructure such as weld seam or heat affected zone in an extremely small area.

Therefore, a novel method is described in this report to determine the material parameters of high strength steel structures and welded joints locally and without any additional effort to perform the tensile test. In this method, instrumented indentation technique (IIT), an indenter is pushed on the flat surface of a specimen in a certain period of time and simultaneously the applied force and the corresponding indentation path are measured. The data related to the force-indentation diagram is given as input to an artificial neural network (ANN) to obtain the material parameters. The ANN can be trained by generating the large qualitative data sets with numerical simulation of the IIT procedure. more information

|

| P 1016 – Development of a new self-piercing solid-rivet system for joining ultra-high strength steels in multi-material structures (IGF-No 18402 N)

The aim of the research project is the development of a modified self-pierce riveting technology for joining ultra-high strength sheets with aluminum alloys. This is done by modifying the self-pierce riveting with solid rivets in such a way that it works without embossing ring on the die side tool. For this purpose the embossing contour is arranged directly under the head of the rivet. Compounds which are produced with the novel method of self-locking self-pierce riveting should then show low processrelated deformations and a good adhesive bond. In the research project, the numerical simulation was used to optimize the geometry of the new riveting technology, which was validated by experimental investigations. On the basis of process analysis, the flexibility of the developed method was determined. In addition, the hybrid joining process was optimized and the bonding properties of the process were recorded. more information

|

| P 1028 – Fatigue strength analysis of bonded steel joints under multiaxial loading conditions (IGF-No 18107 N)

A reliable fatigue life analysis of bonded steeel joints under cyclic loads has a high priority in structural car body engineering. Currently there are no concepts which are recognised as generally valid and which are easy to use at the same time. Therefore, the solution of most engineering tasks with steel adhesive joints requires experimental effort. Aggravating this situation, the general case with loads acting in different spatial directions simultaneously is faced in practice. In the case that there is e. g. a phase shift within the load-time signals, the local stress state is no longer proportional to the applied loads. This so-called non-proportional loading can have a considerable effect on fatigue life and has therefore to be accounted for in the fatigue resistant design of bonded steel joints. Up until now, this general case of loading has not been considered with bonded steel parts. more information

|

| P 1131 – Alloy concepts and process strategies for presshardening steels with increased residual formability (S 024/10224/15)

An effective way to reduce the emissions of passenger cars is to reduce the weight of the vehicle. The greatest potential for savings lies in the area of body design, where high-strength steels are now replacing conventional sheet materials. However, the use of ultra high-strength steels to increase vehicle safety in the event of a crash is particularly challenging. One of the most efficient processes for manufacturing crash-resistant components, such as the B-pillar, is press-hardening, in which forming and hardening are combined in a single process step. Currently, the material 22MnB5 (1.5528) is used at the industrial series production of press-hardened components, but the material ductility in the press-hardened state is limited due to the alloying concept. An improved property profile of strength and residual formability is sought for increased passenger’s safety in the event of a crash. This project therefore deals with the development of new alloying concepts and process strategies to improve the residual formability of press-hardened steels. more information

|

|

|

|