|

Dear Sir or Madam,

Today we would like to inform you about upcoming events with FOSTA participation and about newly published FOSTA final reports from the focus areas mobility, civil engineering as well as plant and mechanical engineering. You can find the FOSTA final reports in the stahldaten.de store.

We wish you interesting reading, happy Christmas holidays and a good start into the new year 2023.

Your FOSTA team

| | 16. bis 17. May 2023

Hochfester Stahl im Stahl- und Anlagenbau -Haus der Technik, Essen-

The event reports on the FOSTA research cluster HOCHFEST, which deals with the processing of high-strength steels in steel construction and mechanical engineering in several subprojects. HOCHFEST was established about 3 years ago and, with the help of steel application research, identifies precisely those technical-scientific issues that can contribute to the improvement of design and construction rules, the further development of design and application techniques, and the expansion of areas of application for high-strength and ultra-high-strength steels in steel construction and mechanical engineering. The event will also present research projects currently in progress that have been initiated since the start of HOCHFEST and address complementary issues. All in all, the event will provide an overall picture of 35 current FOSTA research projects on the application and processing of high-strength steels. It gives participants from industry and academia the opportunity to discuss the content of the projects, to receive further training and to network in this subject area.

The program will be published in 2023. From that time there will also be the possibility to register.

Route description

|

12. bis 16. Juni 2023

METEC & 6th ESTAD (European Steel Technology and Application Days)

ESTAD thrives on high-quality technical presentations and cutting-edge know-how. The high quality standard runs through all main topics and makes this conference one of a kind.

Due to high demand the deadline for the call for papers will be extended!

Take advantage of the possibility to present your newest technological developments and research results at one of the most important steel conferences.

The new abstracts submission deadline is 31 January 2023.

more information

| P 1152 – An approach to numerical determination of hardness evolution in the tool surface layer due to thermal loading during hot stamping (IGF-No 19518 N)

A process for the production of components with tailored properties is given by socalled tailored tempering with strongly heated tools (approx. 500°C), which is based on conventional hot stamping. In this process, the critical cooling rate of 22MnB5 is deliberately undercut and the formation of martensite in the component is suppressed. The increased tool temperature and the press forces that occur lead to a higher thermal load on the tool engraving and ultimately to wear phenomena that are dependent on the hardness evolution and the tempering effects that occur. This affects the dimensional accuracy of the components and the tools have to be reworked or even renewed in a cost- and time-intensive manner. More precise knowledge of the processes in the tool surface and their consideration in the numerical process design contribute to a significant increase in process understanding. The heat transfer between workpiece and tool is another important aspect. more information

|

| P 1195 – Consideration of sequence effects on the fatigue life prediction for tubular sections (IGF-No 19410 N)

The use of hollow sections to build up lightweight structures is common and used by many industrial sectors, like the crane industry, the agricultural and transportation industry as well as for steel bridge constructions. In general this structures build up as truss or frame construction. Especially high and ultra high steel grades are used for an economical design of these structures. In case of the appearing cyclic loads, these type of structures have to be designed to avoid fatigue damage by the use of linear damage accumulation. By common standards and recommendations there is the opportunity to convert the occuring stress ranges to a constant amplitude loading with the equivalent damage by using the Palmgren-Miner-rule. The maximum amount of damage that can be sustained varies depending on the applied standard between a damage sum of D = 0; 2 − 1; 0. To determine the damage sum, influence factors like the load sequence shape, the influence of overloads, welding residual stresses and their reduction under variable amplitude loads, as well as possible load sequence effects are not taken into account, which can lead to uneconimc structures.

The aim of this research project was to check the quality of prognosis on the linear damage accumulation according the Palmgren-Miner-rule by a large test program. Influence factors like the shape of the load spectrum applied, the influence of overlaods, the residual stress variation under variable amplitude loading and possible load sequence effects for constructions made of hollow sections were taken under review. The test results should be used to develop an adapted design recommendation for the linear damage accumulation. more information

|

| P 1203 – Fatigue Life Assessment of Laser Beam and Laser Hybrid Welded Crane Structures made of High-Strength Steels (IGF-No 19272 N)

Motivated by the utilisation of the highest steel grades currently available on the market, also in joints, the research project aims at the reliable and fatigue-related use of laser beam and laser hybrid welded joints made of high-strength and ultra-high-strength finegrain structural steels. Specifically, this applies against the background of the application in highly stressed areas of load-bearing structures, such as they occur in tensile areas of the telescopic boom of mobile cranes. Four fine-grained structural steels of different strength classes, one (very) high-strength (S960) and three ultra high-strength

(S1100 and S1300), produced in different manufacturing processes (quenched-tempered and thermomechanically rolled), constitute the basis for this investigation. more information

|

| P 1262 – Impact of production-related tolerances of the failure and deformation behavior of mechanical joints under crash loading (IGF-No 20116 N)

Mechanical joining techniques are getting increasingly important in the manufacturing of modern car bodies. Compared to the conventional thermal joining techniques such as the spot welding, mechanical joining techniques can be used to join a broad spectrum of different materials. The construction with mixed materials offers an effective way to reduce the full body weight especially against the background of the increasing demand for resource-saving complete vehicles. Mechanical joining process are normally used in a fully automated manner, therefore tolerances in the characteristics of a joint can occur. These tolerances can have an influence on the load bearing capacity and failure behavior of the joint. Subject of this project is the experimental and numerical investigation of the influence of manufacturing flaws on the load bearing capacity and failure behavior of mechanical joints. A methodology has been developed with which it is possible to integrate the observed influence of manufacturing flaws in the crash simulation of vehicle structures.

Different manufacturing influences (rivet length, rivet head end position, orthogonality, lateral offset and flange overlap) were investigated for several joining processes (semitubular self-piercing riveting, bolt setting and flow drill screwing). Therefore corresponding joints taking the manufacturing flaws into account have been manufactured. more information

|

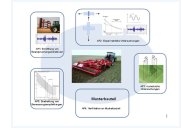

| P 1279 – Design recommendations for the materialefficient use of high strength steel hollow sections in agricultural soil-working machines (IGF-No 19697 N)

The demands on the performance of modern agricultural machinery and equipment are constantly increasing and the accompanying development faces enormous challenges. In view of these development trends, a conflict of objectives arises between the required performance, the permissible machine weights and the economically available cost framework.

This problem is addressed in the project and investigated on the basis of agricultural tillage machines, which include, for example, tillers, cultivators, harrows and plows. These tillage machines offer great potential for the lightweight and material-efficient use of higher-strength steels, as they are profile-intensive structures in which standard materials (e.g. S355) are traditionally used. The structural design is usually based on experience without knowledge of the exact loads, which makes it difficult to achieve an optimal and appropriate design. Within the scope of the research project, an equivalent load spectra for soil cultivation equipment is created. Therefore realistic test runs with a soil tillage implement are performed. The developed load sprectra forms the basis for the operationally stable design of agricultural soil cultivation equipment. more information

|

| P 1296 – Strengthening due to bonding technology of fatigue damages for designs used in steel construction (IGF-No 19963 N)

In steel construction, unforeseen fatigue damage can occur in structures subjected to cyclic loads, making repair measures necessary. Adhesive bonding technology is a promising alternative to the traditional strengthening methods. The aim of the research project was therefore the development and analysis of concepts for the adhesive reinforcement of fatigue damage through the use of bonded “steel patches” for steel structures, considering defined site-specific conditions of use. Within the framework of the completed research project StressPatches, the strengthening of typical steel structure notch details by means of bonded steel patches was investigated. more information

|

| P 1327 – Optimized design of combined steel walls for the installation phase and the final state (IGF-No 19937 N)

The overall objective of the research project is the optimization of design procedures of combined steel sheet piles used in quay wall construction for the protection of terrain jumps. For this purpose, the following objectives are defined:

- The design is carried out without taking the installation process into account. The influence on the final position and thus also on the design are to be checked. (Objective 1)

- Furthermore, the surrounding soil is not considered as resistance in the combined verification against buckling and lateral torsional buckling, and the loadbearing behaviour in the final state is underestimated. There is a lack of incentives to consider soft soils and stratified subsoil structures. (Objective 2)

- For the flanges of the king piles, global internal forces and local influences from flange bending are currently only roughly considered by a reduction of the yield strength. Load reserves with separate consideration are to be examined. (Objective 3)

- Either only plastic or only elastic moment resistances are assigned to the intermediate piles for the determination of the load-bearing capacity. The application of partially plastic resistances shall be investigated. (Objective 4)

more information

|

| P 1328 – Future viability of cold-formed steel profiles in building structures (IGF-No 19964 N)

Thin-walled, cold-formed steel profiles are used in a wide range of areas from industrial steel construction to rack structures and special applications like viticulture. Due to the broad spectrum of applications, the variety of individual, user-specific profile shapes with corrugations, flanges and lips as well as perforations is very large. DIN EN 1993- 1-3 is available for design purposes. However, this was developed essentially for Cand Z-shaped purlins and for typical trapezoidal sheetings, so that its applicability is limited for the multitude of other types of cold-formed profiles. For profiles with perforations, a design is usually even completely impossible. In addition, the application of DIN EN 1993-1-3, even for simple cross-section shapes, is time-consuming and complicated due to the highly complex, overlapping stability shapes and provides conservative results. The aim of the research project was therefore to develop a new, Eurocode-compliant design concept, by avoiding the complicated effective width method of DIN EN 1993- 1-3 and using modern finite strip software for eigenvalue analysis. more information

|

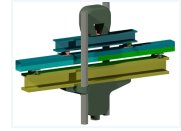

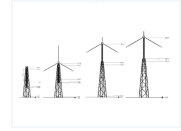

| P 1392 – Self erecting onshore wind turbines with hub height greater than 120 m – Hybrid tower with lifting device for self erection (IGF-No 20604 N)

Economic crane concepts for the erection of wind turbines reach their limits from hub heights of 140 m, as from this height special crawler cranes must be used, the rental costs of which are significant. Their indirect costs should not be neglected either: for example, bridges and roads must be reinforced to allow the passage of the crane transport trucks, and the site itself may have to be prepared at great expense to create a flat surface large enough for the large crane structure. For this reason, intelligent solutions that avoid the need for large special cranes have been sought for some time. In this research project, a self-erecting wind turbine with a steel hybrid tower was developed that does not require the use of special crawler cranes. The tower of the sample system consists of an 80 m high lattice tower with a special transition piece, through which the 100 m high tubular steel tower including nacelle and rotor is lifted into its final position with the help of a strand lifting system. more information

|

|

|

|