50 Jahre FOSTA e. V.

Press hardening of ultra-high strength steels

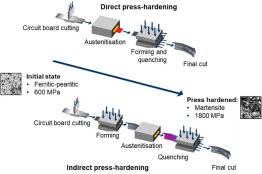

Press hardening combines the processes of hot forming and hardening in one process step [1]. The principle was patented by the Swedish steel producer Norrbottens Järnverk AB in 1977 [2]. The automobile manufacturer SAAB AB first used press-hardened body parts in its 9000 model in 1984 [3]. In the years following, the importance of press hardening of ultra- high strength steels in the course of lightweight body construction grew steadily. Nowadays, two main types are distinguished: direct [4] and indirect [5] press hardening. The respective process steps are shown in Fig. 1. In addition, components with tailored properties can be produced with different process strategies for partial press hardening [6].

Due to the great interest of the automotive industry and the ever increasing demand for press hardened components [7], the process has been in the focus of science for several years.

Also the FOSTA e. V. addressed this topic early on, initiating and accompanying numerous precompetitive research projects to date. The design of a process window for press harden- ing was fundamentally investigated in the framework of the FOSTA project P 644. Another FOSTA project (P 709) has been dealing with the realisation of functionally optimised com- ponents using Tailor Welded Blanks during press hardening. Further fundamental investiga- tions concerning the tribological conditions in press hardening, which have a great influence on the forming behavior due to high thermo-mechanical stress, were carried out in the FOS-

TA project P 871. In the FOSTA project P 902, the combination of hydroforming and press hardening took place. It showed that formless solids represent a potential alternative to gas- eous active media. To determine the optimal removal time of the component and the more economical design of the process, a tactile temperature sensor based on thin film technology was developed in the FOSTA project P 1065. Current projects include the qualification of the shear cutting as a manufacturing process for the trimming of ultra-high strength chromium steels, which represent a possible alternative to conventionally used 22MnB5 (P 1222) and the tool-side influence on the tribological conditions during press hardening (P 1228). In addi- tion, in project P 1238, locally thinned areas are to be incorporated into the component in order to improve their joinability.

Thus, the FOSTA e. V., with its supervised research projects, makes a decisive contribution to the further development of press hardening of ultra-high strength steels.

Marion Merklein, Bernd-Arno Behrens, A. Erman Tekkaya

Sources

[1] Merklein, M.; Lechler, J.: Investigation of the thermo-mechanical properties of hot stamping steels. Journal of Materials Processing Technology 177. 1-3 (2006), S. 452–455

[2] Ridderstråle, C.-E.: Manufacturing a hardened steel article. GB1490535 (A). Norbottens Jaernverk AB, Schweden, 1974

[3] Burglund, G.: The history of hardening of boron steel in northern Sweden. In: Steinhoff, K.; Oldenburg, Mats,Braham Prakash (Hrsg.): Proceedings of the 1st International Conference on Hot Sheet Metal Forming of High-Performance Steel. Bad Harzburg, 2008, S. 175–177

[4] Dick, P.; Schweiker, T.; Mattes, U. et al.: Warmumformung bei Daimler - Ein heiß diskutiertes Verfahren. In: Merklein, M. (Hrsg.): 3. Erlanger Workshop Warmblechumformung. Meisenbach. Bamberg, 2008, S. 41–55

[5] Merklein, M.; Lechler, J., Stoehr, T.: Characterization of tribological and thermal properties of metallic coatings for hot stamping boron-manganese steels. Proceedings of the 7th International Conference Coatings in Manufacturing Engineering (2008), S. 219–228

[6] Feuser, P.: Simulation eines partiellen Presshärteprozess unter Berücksichtigung thermomechanischer und metallurgischer Zusammenhänge. In: Merklein, M. (Hrsg.): 6. Erlanger Workshop Warmblechumformung Meisenbach. Bamberg, S. 37–57

[7] Schuler Pressen GmbH: „Formhärten mit PCH Flex - Flexibel, Effizient, Produktiv“,

https://www.schulergroup.com/major/download_center/broschueren_hydraulic_press/download_hydraulic_press/hydraulic_press_leichtbau_broschuere_formhaerten_pch_d.pdf, Aufrufdatum: 09.03.2018